AFLO transforms the traditional idea of ductwork by introducing a new system designed to meet the needs of investors, designers, installers, and maintenance professionals.

Thanks to its patented technological features, AFLO system® is a cutting-edge solution in every respect.

Its performance makes it the ideal answer to challenges encountered during the design, installation, and maintenance phases of air systems.

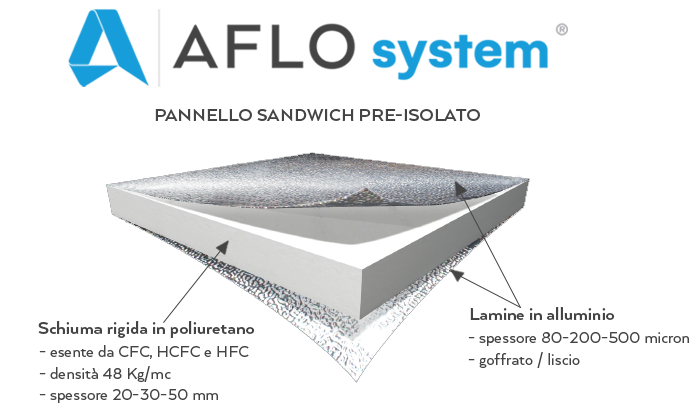

A high-performance pre-insulated sandwich panel featuring high-density, closed-cell rigid polyurethane foam, expanded without the use of fluorocarbons in compliance with EU regulations, and coated on both sides with pre-painted aluminum sheets for complete UV protection.

This design allows AFLO system® ducting to be installed outdoors, ensuring durability for over 30 years.

Designing, installing, and maintaining air systems today means making a responsible choice for uncompromising efficiency, where technological solutions and maximum sustainability serve to genuinely improve system performance.

AFLO system® technology effectively meets the challenges of increasingly complex HVAC systems,

while enhancing safety throughout their application.

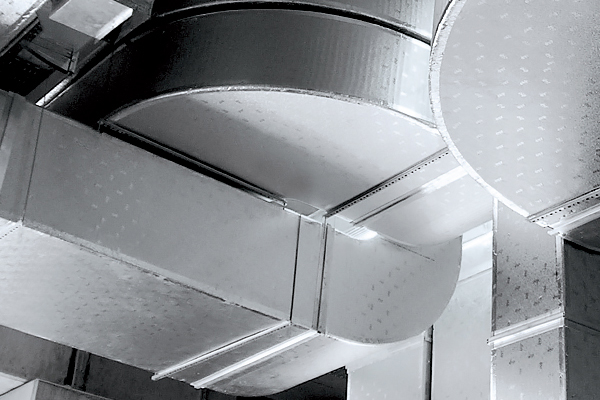

AFLO system® ducts are the ultimate solution for air distribution, suitable for any environment, application, temperature, operating pressure, air velocity, and required size.

AFLO system® ducts contribute to air distribution in millions of projects across more than 108 countries, serving a wide range of application sectors.

AFLO system® makes building air systems convenient and safe: the low weight of the materials (less than 1/7 of a traditional duct) eliminates handling and management issues associated with insulated sheet metal ducts. The application is practical and safe, with lower risks on site, as well as significant advantages for both assembly and transport.

The features of AFLO system® ducts ensure a significant reduction in construction time (-50%) and installation time (-80%), while allowing on-site modifications. They also provide ease of cleaning and maintenance, as well as substantial savings on mounting structures.

The internal lining of the panel is in bacteriostatic aluminum, which makes the ductwork capable of not increasing the growth of bacteria on the surface. Cleaning and maintenance are in fact facilitated by the ability of the panel surface to not retain particulate matter, thanks to a profiles junction system able to provide a perfect flatness throughout the panel surface.

AFLO system® ducts are 8–10 times lighter than traditional ducts, offer exceptionally high mechanical rigidity, and have fewer air leakage points, with joint systems that ensure Class C airtightness.

In addition, the characteristics of the insulating material allows for high acoustic comfort, blocking vibrations and resonances inside the duct.

The high-density polyurethane structure determines an insulation that is 2 times more performing, reaching an exceptionally low thermal conductivity, equal to 0.0206 W / mK, with minimal air temperature losses compared to traditional ducts.

AFLO system® ducts contribute to achieving points under LEED, WELL, BREEAM, and Green Building Council standards, ensuring tangible energy savings.

AFLO system® patented panels leverage the physical properties of their materials, including the bacteriostatic nature of aluminum and the excellent insulation performance of polyurethane.

The extraordinary technical features and the proved effects they have on the working operations and on the air quality are the guarantee also for the construction of ductworks with large dimensions.

All the components of the ductwork are 100% recyclable and zero impact materials.

Aluminum is totally recyclable, glues and silicones are water-based without VOC, insulation free from CFC and HCFC enjoys a second life through reuse in the construction chain.

The low weight of the ductwork and the characteristics of the insulating material make the HVAC system anti-seismic, safe in case of fire, in compliance with regulations and with European and international standards.

AFLO redefines the traditional concept of ductwork by introducing a new system designed to meet the needs of investors, designers, installers, and maintenance professionals.

AFLO System® ducts are 8–10 times lighter than traditional ducts, offer exceptionally high mechanical rigidity, and feature fewer air leakage points, with joint systems ensuring Class C airtightness.

Additionally, the properties of the insulating material—providing slimmer insulation—deliver superior acoustic comfort by blocking vibrations and resonances inside the duct.

The high-density polyurethane structure determines an insulation that is 2 times more performing, reaching an exceptionally low thermal conductivity, equal to 0.0206 W / mK, with minimal air temperature losses compared to traditional ducts.

AFLO system® ducts contribute to achieving points under LEED, WELL, BREEAM, and Green Building Council standards, ensuring tangible energy savings.

AFLO system® patented panels leverage the physical properties of their materials, including the bacteriostatic nature of aluminum and the excellent insulation performance of polyurethane.

The extraordinary technical features and the proved effects they have on the working operations and on the air quality are the guarantee also for the construction of ductworks with large dimensions.

All the components of the AFLO system® ductwork are 100% recyclable and zero impact materials.

Aluminum is totally recyclable, glues and silicones are water-based without VOC, insulation free from CFC and HCFC enjoys a second life through reuse in the construction chain.

The low weight of the ductwork and the characteristics of the insulating material make the HVAC system anti-seismic, safe in case of fire, in compliance with regulations and with European and international standards.

Designing, building and maintaining an air ventilation system has never been so simple, economical and sustainable.

AFLO System® solutions offer numerous benefits to all stakeholders, with performance that addresses challenges in both the design and the installation and maintenance phases of the system.

AFLO System® efficiently handles

even the most complex design challenges:

■ Compliant with fire prevention and seismic safety regulations;

■ Suitable for any design scenario;

■ Best-in-class energy performance;

■ Contributes to earning LEED, BREEAM, WELL, and GREEN BUILDING points;

■ Savings on fixings and reduced load on supporting structures.

AFLO System® efficiently handles

even the most complex design challenges:

■ Compliant with fire prevention and seismic safety regulations;

■ Suitable for any design scenario;

■ Best-in-class energy performance;

■ Contributes to earning LEED, BREEAM, WELL, and GREEN BUILDING points;

■ Savings on fixings and reduced load on supporting structures.

AFLO System® efficiently handles even the most complex design challenges:

■ Compliant with fire prevention and seismic safety regulations;

■ Suitable for any design scenario;

■ Best-in-class energy performance;

■ Contributes to earning LEED, BREEAM, WELL, and GREEN BUILDING points;

■ Savings on fixings and reduced load on supporting structures.

Our team is available for information, quotes, and further details regarding AFLO system®.